I've never done a worklog before because most everything on my car has been pretty much "by the book". Nothing super special, complicated, etc. This is something pretty new so i thought you guys might want to check out my progress.

I'll probably just keep updating this first post with info as i go along.

time to let the cat out of the bag and get all of this info together in one place

the stuff you need to pull this off in a FWD BP powered BG:

OE parts needed:

celica alltrac ST165/185/205 shifter and cables.

some are longer than others, beware. ST165 cables are BARELY long enough, that's what i have. the camry stuff will work but the shifter base is huge.

2000ish Camry/Solara v6 5 speed trans

LSD of your choice, buy for 93-95 MR2 turbo

new bolts, bearings, speedo gear, snap ring for LSD

(note, the camry open diff ring gear bolts are TOO SHORT

also note, these transmissions are much more difficult to take apart than the good old G series.)

91-92 MR2 intermediate shaft/bracket

91-92 MR2 drivers side inner axle stub

(note: these are generally inexpensive and work for the all the aftermarket LSD's. If you want to use the stock viscous LSD from a 93-95 MR2 you will need the two parts above from the 93-95. these will fetch inflated prices.)

Celica Alltrac ST185 front axles (hybrid with MR2 inner axles above)

91-92 MR2 cable drive speedo sender

90-94 protege LX speedo cable (fits toyota sender, will also connect to escort speedo)

('88 RX7 balljoints w/ late style BG spindles) -or- (MX3 LCA's) to widen track slightly

Custom purchased parts needed:

custom clutch disc, 8 7/8" OD with 21 spline toyota center hub.

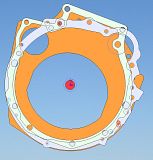

adapter plate (dur)

bushings for mounts - i used Energy suspension #9.9483

Custom machine work and "machine work":

machine off weight ring on back of flywheel to clear plate

deck flywheel down an extra ~0.10" (or have fun last-minute clearancing the bellhousing like i did)

notch bellhousing for starter nose, drill hole for starter mounting bolt

notch bellhousing for front/top adapter plate to engine bolt head

lots of bolt shortening for "blind holes" in the adapter plate

Sh!t you have to make from scratch:

Plate to cover old shifter hole in floor, to bolt new shifter base to

engine/trans mounts and brackets (all four for FWD)

subframe for front/rear lower mounts (you may be able to modify the stock one to work, i didnt bother)

bracket for intermediate shaft bearing

bracket and line for clutch slave (use camry slave, stock master)

Specific tools/skills:

BFH

Welder / how to weld

Torch

drill press or punch

hydraulic press

grinders, cutters, nippers, band saw, etc etc etc

Materials:

Plate and angle steel in various thicknesses and widths (we ranged from 1/8" to 1/2" thick on this project)

round or square steel tubing for subframe (we used 1" square 1/8" wall)

1.5" ID 1/4" wall DOM for mounts (if you use the p/n above)

1/2" diameter bolts for mounts (again)

lots of M10x1.25 and M12x1.5 bolts in various lengths

a handful of nuts, same sizes

a few oddball fasteners, for example the bolts at the front of the subframe were m12x1.0 IIRC

tips:

the engine and trans need to come bothforward and up roughly 1". its hard to say precisely how much. the main issue with the stock drivetrain location is that the inner cv joints hit the K frame, this is the problem you need to solve. i wanted at least a finger's thickness clearance on everything spinning/moving. the frame rail on the drivers side also tries to occupy the same space as the trans by about 1/2". options are notch and box the frame rail, or hit it with the torch and BFH. we went with the BFH, everything seems to be just fine.

i'll be happy to answer specific questions from anyone attempting to do the swap, however i hope that i covered this pretty well. if you feel i have forgotten something major, please let me know so i can fix it.

i know the guys in NZ were first, but as far as i know this is the first FWD toyota conversion in the continental US. i give credit where credit is due, i ask that you all please do the same

I'll probably just keep updating this first post with info as i go along.

Originally posted by 7/23/09

time to let the cat out of the bag and get all of this info together in one place

the stuff you need to pull this off in a FWD BP powered BG:

OE parts needed:

celica alltrac ST165/185/205 shifter and cables.

some are longer than others, beware. ST165 cables are BARELY long enough, that's what i have. the camry stuff will work but the shifter base is huge.

2000ish Camry/Solara v6 5 speed trans

LSD of your choice, buy for 93-95 MR2 turbo

new bolts, bearings, speedo gear, snap ring for LSD

(note, the camry open diff ring gear bolts are TOO SHORT

also note, these transmissions are much more difficult to take apart than the good old G series.)

91-92 MR2 intermediate shaft/bracket

91-92 MR2 drivers side inner axle stub

(note: these are generally inexpensive and work for the all the aftermarket LSD's. If you want to use the stock viscous LSD from a 93-95 MR2 you will need the two parts above from the 93-95. these will fetch inflated prices.)

Celica Alltrac ST185 front axles (hybrid with MR2 inner axles above)

91-92 MR2 cable drive speedo sender

90-94 protege LX speedo cable (fits toyota sender, will also connect to escort speedo)

('88 RX7 balljoints w/ late style BG spindles) -or- (MX3 LCA's) to widen track slightly

Custom purchased parts needed:

custom clutch disc, 8 7/8" OD with 21 spline toyota center hub.

adapter plate (dur)

bushings for mounts - i used Energy suspension #9.9483

Custom machine work and "machine work":

machine off weight ring on back of flywheel to clear plate

deck flywheel down an extra ~0.10" (or have fun last-minute clearancing the bellhousing like i did)

notch bellhousing for starter nose, drill hole for starter mounting bolt

notch bellhousing for front/top adapter plate to engine bolt head

lots of bolt shortening for "blind holes" in the adapter plate

Sh!t you have to make from scratch:

Plate to cover old shifter hole in floor, to bolt new shifter base to

engine/trans mounts and brackets (all four for FWD)

subframe for front/rear lower mounts (you may be able to modify the stock one to work, i didnt bother)

bracket for intermediate shaft bearing

bracket and line for clutch slave (use camry slave, stock master)

Specific tools/skills:

BFH

Welder / how to weld

Torch

drill press or punch

hydraulic press

grinders, cutters, nippers, band saw, etc etc etc

Materials:

Plate and angle steel in various thicknesses and widths (we ranged from 1/8" to 1/2" thick on this project)

round or square steel tubing for subframe (we used 1" square 1/8" wall)

1.5" ID 1/4" wall DOM for mounts (if you use the p/n above)

1/2" diameter bolts for mounts (again)

lots of M10x1.25 and M12x1.5 bolts in various lengths

a handful of nuts, same sizes

a few oddball fasteners, for example the bolts at the front of the subframe were m12x1.0 IIRC

tips:

the engine and trans need to come bothforward and up roughly 1". its hard to say precisely how much. the main issue with the stock drivetrain location is that the inner cv joints hit the K frame, this is the problem you need to solve. i wanted at least a finger's thickness clearance on everything spinning/moving. the frame rail on the drivers side also tries to occupy the same space as the trans by about 1/2". options are notch and box the frame rail, or hit it with the torch and BFH. we went with the BFH, everything seems to be just fine.

i'll be happy to answer specific questions from anyone attempting to do the swap, however i hope that i covered this pretty well. if you feel i have forgotten something major, please let me know so i can fix it.

i know the guys in NZ were first, but as far as i know this is the first FWD toyota conversion in the continental US. i give credit where credit is due, i ask that you all please do the same

Comment